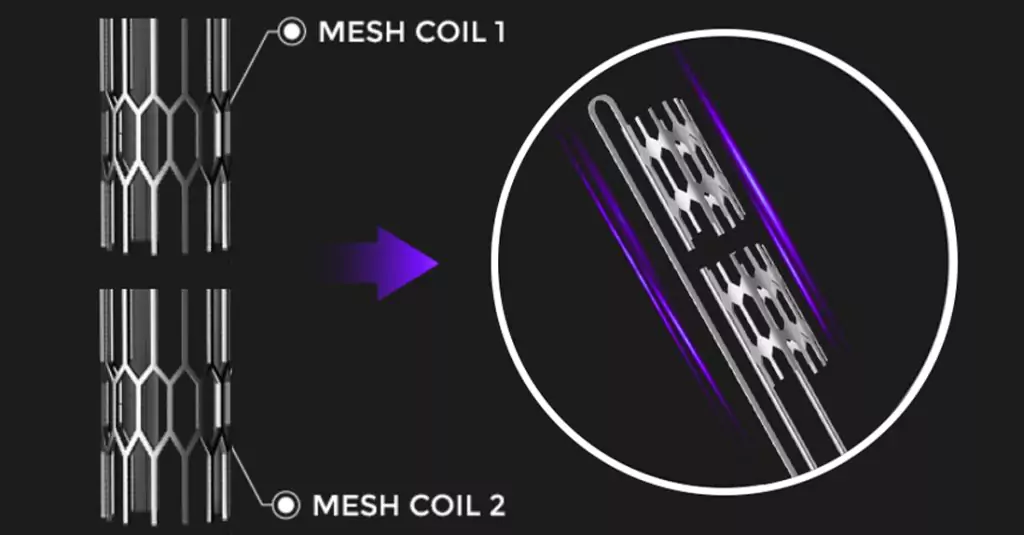

FUUMY, a prominent name in the vaping industry, has built a reputation for its commitment to quality and innovation. Founded in 2019, the FUUMY team has developed an impressive range of products, utilizing cutting-edge technologies and independent intellectual property rights that set them apart in the competitive market. The introduction of advanced product structures, including their unique cotton tank design for disposable vapes, has significantly influenced industry standards. Their exclusive cellular ceramic technology enhances flavor delivery, making FUUMY products a preferred choice among discerning users.

At the core of FUUMY’s philosophy is a belief in continuous improvement and quality management. By integrating superior resources in product design, research and development, and lean manufacturing practices, they have adopted a comprehensive management system that complies with ISO9001 standards. This structured approach ensures that every product undergoes rigorous scrutiny, from conception through to production and distribution. Their in-house laboratory further solidifies their commitment to quality, focusing on coil development and product flavoring, which enables them to respond swiftly to evolving consumer preferences.

Rigorous Quality Control Processes

To maintain its high standards, FUUMY implements rigorous quality control processes across all stages of production. This commitment to quality is evident in their extensive testing protocols, which are designed to assess each product’s performance and reliability. The company conducts thorough evaluations before any product reaches the market, ensuring that it meets not only its internal benchmarks but also the expectations of its users.

Product Testing and Certification

FUUMY’s dedication to quality is exemplified by its robust product testing and certification practices. Each product undergoes sequential phases of testing, where various performance metrics are tracked and analyzed. This exhaustive assessment process verifies that their products function correctly and safely, providing consumers with peace of mind. Furthermore, they actively seek certification from recognized safety and performance standards, showcasing their commitment to excellence and transparency.

Extensive Testing Protocols

The extensive testing protocols include functionality checks, flavor consistency assessments, and safety evaluations. By employing a multi-faceted approach to testing, FUUMY can identify any potential issues before products reach consumers. This rigorous examination not only helps in enhancing product quality but also minimizes the likelihood of recalls or consumer complaints, fostering trust among their user base.

Compliance with International Standards

FUUMY prides itself on its adherence to international standards, which is crucial in the global market. Compliance with recognized regulations assures customers that FUUMY products are developed and manufactured to the highest quality specifications. This alignment with global standards enhances their credibility and reinforces their position as leaders in the industry.

Advanced Manufacturing Techniques

Innovative manufacturing techniques are fundamental to FUUMY’s approach to product development. By leveraging state-of-the-art technology, the company has established a manufacturing process that emphasizes precision and efficiency. This technological advancement plays a vital role in ensuring that each product is produced consistently, meeting the exacting standards set by FUUMY.

State-of-the-Art Technology

The incorporation of state-of-the-art technology into the manufacturing process allows FUUMY to optimize production capabilities. By utilizing automated systems, they can achieve higher levels of efficiency while reducing the risk of human error. Additionally, these technologies enable precise control over various production parameters, ensuring that products are manufactured with utmost accuracy.

Automation and Precision in Production

Automation is integral to FUUMY’s production process, facilitating a level of precision that is essential for high-quality outputs. Automated systems not only streamline operations but also ensure that each product is made with the same meticulous attention to detail. This level of consistency is vital in building brand reputation and consumer trust.

Use of Advanced Materials

In pursuit of quality, FUUMY is dedicated to using advanced materials that enhance product performance. By carefully selecting materials that offer superior durability and flavor enhancement, the company ensures that its products meet the demands of its consumers. This commitment to quality materials contributes to the overall satisfaction and loyalty of their customer base.

Skilled Workforce

Behind FUUMY’s success is a highly skilled workforce dedicated to excellence. The company prioritizes its employees’ development through continuous training programs aimed at honing their skills and knowledge in quality assurance and manufacturing processes. This focus on employee development reflects FUUMY’s commitment to upholding high-quality standards throughout their organization.

Expertise in Quality Assurance

The expertise of FUUMY’s workforce in quality assurance is indicative of their dedication to outstanding product quality. Employees are trained to identify and resolve potential issues proactively, ensuring that the highest standards are upheld throughout the production process. This collective expertise enables FUUMY to maintain its leading position in the market, which is consistent with its pledge to quality management.

In conclusion, FUUMY’s commitment to rigorous quality control processes, advanced manufacturing techniques, and skilled workforce ensures that its products stand out in the vaping industry. Through extensive testing, compliance with international standards, cutting-edge technology, and a dedicated team, FUUMY has established a robust quality management system that resonates with consumers seeking reliable and innovative vaping solutions.

Customer Feedback and Continuous Improvement

Surveys and Questionnaires

FUUMY values consumer insights and acknowledges that customer feedback is a vital component in their quality management strategy. To gather this information, they conduct surveys and questionnaires that target various aspects of the user experience, from product satisfaction to suggestions for future improvements. By analyzing the data collected, FUUMY identifies patterns and trends that inform product development and refinement, ensuring that its offerings remain aligned with user expectations and preferences. This emphasis on customer feedback enables FUUMY to adapt quickly to market demands, enhancing consumer loyalty and satisfaction.

Implementing Changes Based on Feedback

In response to the feedback collected, FUUMY commits to making meaningful changes that enhance their product offerings. These adjustments are not only limited to product features but also extend to internal processes that drive efficiency and effectiveness. Through agile methodologies, FUUMY can rapidly implement modifications based on consumer insights, ensuring that they stay relevant in a fast-paced marketplace.

Product Adjustments

When customer feedback indicates a specific need or concern regarding their products, FUUMY takes action to implement adjustments. This could involve refining flavors based on user preferences or enhancing the usability of disposable vape designs. By directly addressing consumer suggestions, FUUMY not only meets their needs but also demonstrates a proactive commitment to quality. This responsiveness builds trust and reinforces customer connections, encouraging ongoing engagement with the brand.

Process Improvements

Beyond product adjustments, FUUMY evaluates its internal processes regularly, looking for ways to enhance operational efficiency. By examining workflow efficiencies, resource utilization, and production timelines, the company can optimize its manufacturing practices without compromising quality. These continuous process improvements reflect FUUMY’s dedication to delivering high-quality products while maintaining agile operations that can keep pace with consumer demands.

Commitment to Sustainability and Ethical Practices

Sustainable Sourcing of Materials

A critical element of FUUMY’s quality management is its commitment to sustainability and ethical manufacturing practices. FUUMY understands that responsible sourcing of materials is vital in creating products that not only perform well but also minimize environmental impact. By prioritizing eco-friendly materials, FUUMY’s product life cycle becomes more sustainable, reflecting its dedication to both quality and environmental responsibility.

Eco-friendly Materials

FUUMY actively seeks to incorporate eco-friendly materials into their product designs. This initiative includes using biodegradable components whenever possible, thus reducing waste and promoting a circular economy. By investing in sustainable materials, FUUMY not only ensures that its products are better for the environment but also appeals to a growing consumer base that prioritizes eco-conscious brands. This practice underscores FUUMY’s philosophy of harmonizing quality with environmental responsibility.

Ethical Manufacturing Practices

FUUMY recognizes that ethical manufacturing practices contribute significantly to their overall product quality. These practices not only ensure that the products are made under humane working conditions but also help the company maintain its integrity and reputation within the industry. By adhering to strict guidelines and regulations regarding labor standards, FUUMY fosters a positive working environment that indirectly enhances product quality.

Fair Labor Policies

At the heart of FUUMY’s commitment to ethics in manufacturing is the application of fair labor policies. This entails ensuring that all workers are compensated fairly, work in safe conditions, and have access to proper training and development opportunities. Such practices cultivate a motivated workforce that takes pride in their work, translating to superior craftsmanship and attention to detail in every product. FUUMY’s strong stance on labor rights demonstrates their commitment to being a responsible player in the industry.

Environmentally Conscious Operations

FUUMY’s dedication to sustainability goes beyond material sourcing and ethical labor practices. The company is invested in environmentally conscious operational strategies that aim to minimize carbon footprints and waste. This includes implementing energy-efficient production technologies and waste recycling systems throughout the manufacturing process. By embedding sustainability into its core operations, FUUMY ensures that its quality management processes are aligned with its overarching commitment to protecting the planet.

In conclusion, FUUMY’s unwavering focus on customer feedback, continuous improvement, sustainability, and ethical practices sets them apart in the vaping industry. Through comprehensive surveys and actionable insights, they ensure that their products meet and exceed customer expectations. Their dedication to sustainable sourcing and ethical manufacturing practices not only enhances product quality but also fosters brand loyalty within a conscientious consumer base. By weaving these principles into the fabric of its operation, FUUMY continues to redefine quality management in the vaping market, establishing itself as a forward-thinking leader.