The popularity of vapes led to the rise of the vape cartridge manufacturing industry, which has become an important industry in the market today. As an integral part of vape, the quality and design of the cartridge is critical to the user experience. In this article, we will explore how vape cartridges and vape pens work, the process of making a vape cartridge and how to find a reliable supplier of vape cartridges, as well as how to ship vape pens and vape cartridges, we will also discuss maintenance time.

How do a vape cartridge and a vape pen work?

To begin, it is important to comprehend the functionality of both a vape pen and its corresponding cartridge. Typically, a vape cartridge encompasses an integrated mouthpiece along with a coil that enables direct attachment to the vape pen by the user for immediate use. The essential task of powering up this process falls on the shoulders of the vape pen; its generated power serves to transform the contained liquid into vapor via a heat induction mechanism instigated by a heating coil. This subsequently makes possible the act of vaping.

How to manufacture a vape cartridge?

In our subsequent discussion, we will discuss the intricate process involved in the manufacturing of vape cartridges. This multi-step procedure begins emphatically with the selection of superior raw materials. The fundamental quality of a vape cartridge is intrinsically tied to these raw materials; hence it’s crucial for manufacturers to meticulously source and acquire only those that meet their stringent standards. The caliber of e-liquid, an essential constituent within vape cartridges, influences both taste and security aspects of the final product straightaway. As such, manufacturers are obligated to validate not only its impeccability but also its stability as they steer clear of substandard ingredients posing potential health hazards. Central to this discourse is also the principal production technology utilized in creating vape cartridges—prospectively patrons should only consider reputable producers equipped with state-of-the-art machinery for this task. Quality consistency across all batches can be assured if rigorous control mechanisms scrutinize each step—from procurement right through production oversight up until inspection post-production. Through strict quality control protocols being enforced throughout every stage, what materializes is a commitment from manufacturers that each manufactured unit garners compliance while ensuring consumers imbibe reliable vaping experiences consistently.

In the field of vape cartridge manufacturing, having relevant certificates is a reflection of a manufacturer’s strength and credibility. For example, ISO certificates and HACCP certificates are both important standards that measure a manufacturer’s quality management and food safety. These certificates not only prove that the manufacturer follows strict norms and standards in the production process, but also increase consumers’ trust in the products.

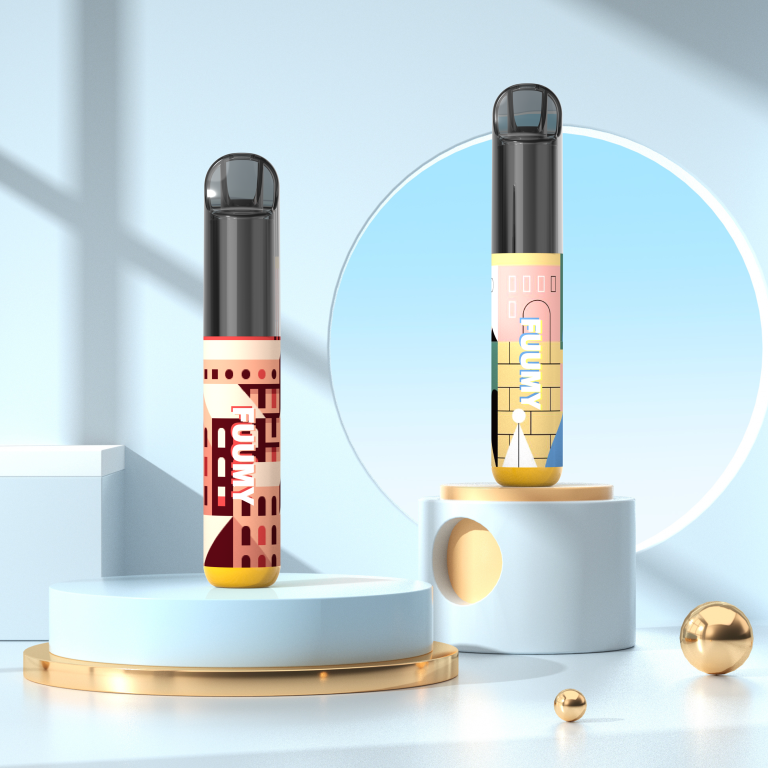

Among other things, Fuumy has implemented a Samsung production system, which complies with ISO 9001 standards. And our company has a high level of clean room and advanced production equipment, dedicated to improving product quality and production efficiency, which can guarantee your supply. At the same time, FUUMY has established a comprehensive manufacturing center that can track multiple control steps from incoming materials to outgoing goods to ensure product quality and safety.

Where can I find a supplier of vape cartridges?

Choosing the right supplier is critical for companies looking to enter the vape cartridge manufacturing industry or find suppliers of vape cartridges. Most of the suppliers and manufacturers of vape cartridges are located in China, and these companies provide high-quality vape cartridges to the global market with their rich production experience and advanced manufacturing technology. Among them, Fuumy has won the favor of many customers with its excellent quality and professional service, and its customers are all over the United States, Europe, Russia, the Middle East and Southeast Asia.

Transportation and shelf life of vape pens and vape cartridges

Let’s talk about the transportation and shelf life of vape pens and vape cartridges. During transportation, manufacturers need to take proper packaging measures to ensure that vape cartridges and vape pens are free from damage and leakage during transportation. Meanwhile, the shelf life of vape cartridges and vape pens is also a major concern for consumers. Manufacturers need to indicate the production date and shelf life on the product packaging to ensure that consumers are aware of the storage and usage period of the products before use.

Conclusion

To summarize, vape cartridge manufacturing is an industry that involves several links and complex processes. From raw material selection and production process control to quality control and certification, manufacturers need to take a serious approach to ensure the quality and safety of their products. At the same time, choosing the right supplier and focusing on product transportation and shelf life issues are also key to ensuring a quality experience for consumers. With the continuous development of the vape market, it is believed that the vape cartridge manufacturing industry will usher in a broader development prospect in the future.